It has a long life span. It is resistant to high pressure and impact. It is easy to load, transfer and lay. High level of elasticity provides an easy montage. It is durable. It does not get affected from underground movements and break. Appropriate to be laid undersea. It does not get affected from sea water and sea movements. It has resistance to chemicals and ability to work in acidic, basic and salty environments. It does not get affected from corrosion, decay and it is not abraded. Due to the catalysts it includes, it has high resistance to solar rays. It can be produced as coil or length. Due to its perfect welding ability, it does not break from the joints under pressure and provides impermeability.

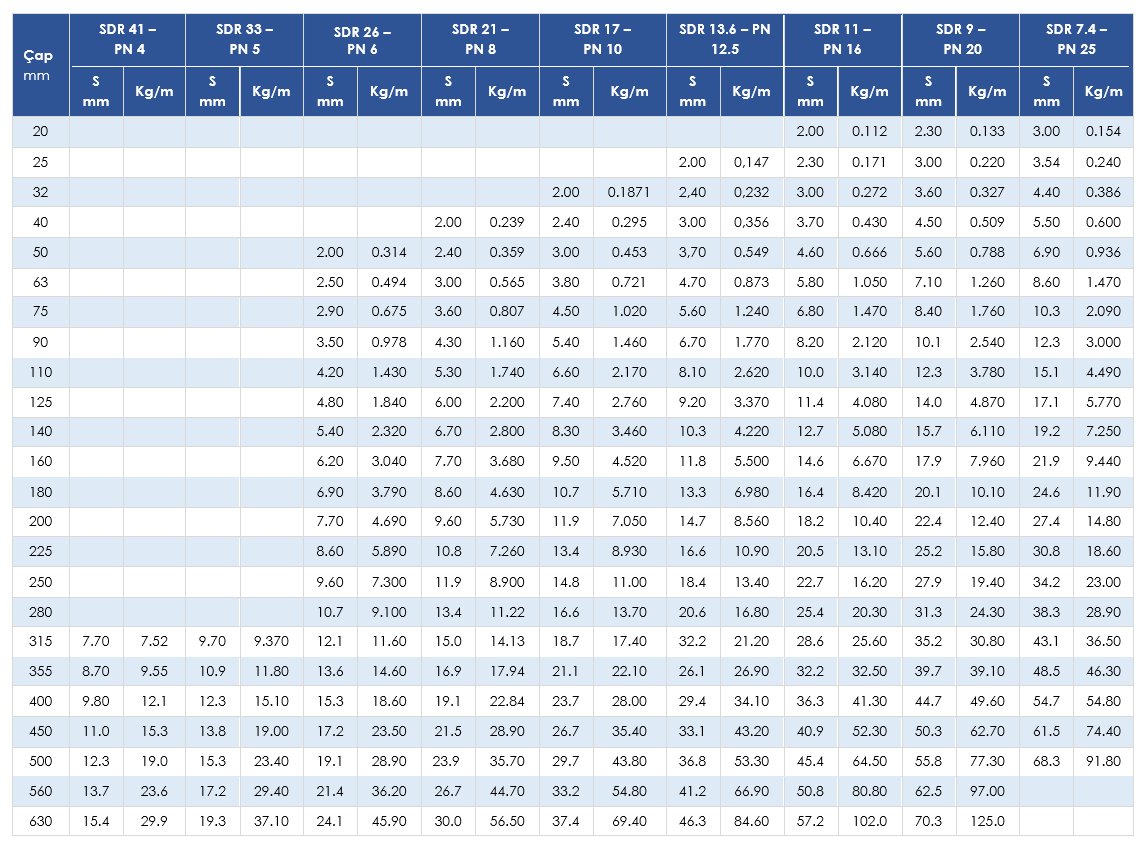

It can be produced at any pressure class from PN 4 to PN 32 and depending on the request.